Spray and Fuse Hardfacing

Spray and Fuse Hardfacing

Spray and Fuse coatings have a metallurgical bond with the basematerial; the other coating processes are a mechanical bond.Spray and Fuse coatings will take more physical abuse and stillmaintain its bond to the base material. They are also moreresistant to chipping than the other coating processes.

Because of the high percentage of Nickel or Cobalt in the Sprayand Fuse coatings,they will not rust.

Spray and Fuse coatings maintain a higher degree of its initialhardness as part temperatures rise.

Spray and Fuse coatings will not anneal,they will regain theiroriginal hardness when the part temperature returns to ambient.

Advantages of coating

High density and zero porosity

High interface bond strength and metallurgical bonding-High hardness up to HRC 67

Nickel or cobalt-based self-fluxing alloy can be applied for600 C℃, wear resistance, corrosion resistance,shock resistance.

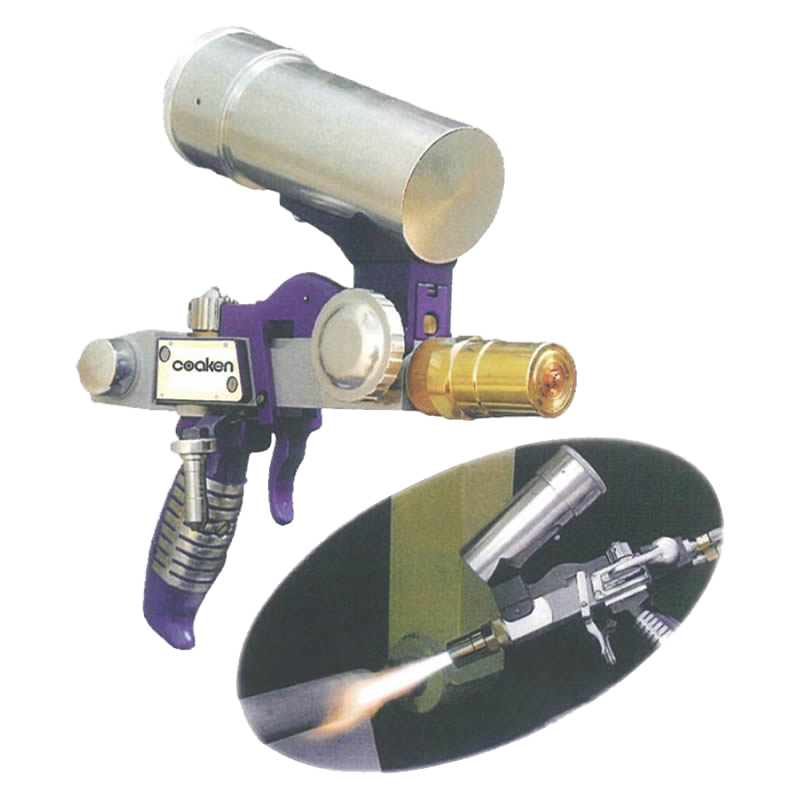

Coaken Techno-PJ.85(From Japan)

CastoDyn-DS-8000(From Switzerland)